Agricultural anaerobic digestion

How can you secure and improve the profitability of your operation?

You are an operator or in charge of biological monitoring of an agricultural anaerobic digestion unit and you have few indicators to monitor its biological health. You don’t know if your digesters are working optimally or not:

- Can I increase the profitability of my unit?

- Is my facility biologically secure?

- What indicators can I put in place to improve the biological safety of the units and their profitability?

- What will be the impact of a new waste on my digester and how can I get the answer quickly?

BioEnTech’s solutions adapt to the typologies and variabilities of substrates (stable or changing rations).

Download the case study

How to make money, secure and correct the biology of my digester ?

For a unit of 250 kWe in co-generation, a loss of 5% of bio-methane over one year results in a loss of about €20,000 on electricity revenues.

The objective of a anaerobic digestion unit is to reach its optimum production as quickly as possible and, above all, to maintain this rate for as long as possible.

Few people fully understand the meaning and interpretation of laboratory analyses. Throughout the life of a digester biological monitoring is essential. It is even more so during the critical phases of startup and instability. The methods currently on the market based on FOS/TAC are unreliable and provide only partial, incomplete information on biological monitoring parameters. BioEnTech supports and secures the load increase of the unit with the help of SNAC (co-developed with INRAE) and associated interpretation support services.

BioEnTech guarantees the biological safety of your anaerobic digestion unit.

How can I quickly know if an unknown substrate is compatible with the biological state of my digester?

Characterization tests are often long and imprecise because the variability of the results is very important between different laboratories.

BioEnTech has co-developed with INRAE a reliable and standardized technique to quickly characterize inputs (IR-SCAN®).

How to biologically secure my unit and test a new recipe?

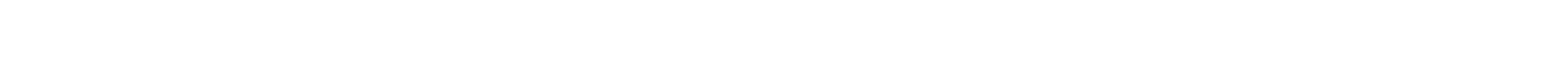

MeMo® allows to visualize the current biological state of your digester in real time and to understand how the drifts (slow and fast) of biological parameters are set.

MeMo® allows you to virtually test day-to-day recipes on your facility to anticipate biological drifts.

The benefit of BioEnTech’s tools is to set production caps, anticipate drifts while adapting to the operating constraints of an agricultural unit.

Anaerobic digestion has long been considered a virtuous product, but it is sometimes difficult to control with all variations and variables. BioEnTech is one of the few players to offer an all-in-one solution, because a anaerobic digestion plant requires several biological, technical and scientific know-how.

An advice, a tip, get in touch with us!

We are at your disposal, whatever the size of your unit and your bioprocess is, our teams promote proximity work with your teams.

Each project is studied on a case-by-case basis and BioEnTech solutions are customizable.

Some examples of supported collective activities:

You are:

Site manager / Agricultural unit operator

Understanding the malfunctions

Anticipating the problems.

Concrete solutions on the ground

Builder

of agricultural unit

Innovate and stand out with

digital solutions

Real-time biological

monitoring and feeding

recommendations

Engineering Office/ Project Assistant

Commissioning and Loading increase

Improving the biological functioning of the site

Increase your customer’s profitability