Collective methanization

Can your losses due to biological malfunctions be anticipated? How can these risks be prevented?

At a collective anaerobic digestion facility, the nature of the bio-waste supplies you receive and their valorisation are difficult to anticipate on a day-to-day basis. Moreover, your storage capacities are very limited and you don’t necessarily have the time and flexibility to make the mixtures adapted to the biology of the digester.

Download the case study

Are there tools to be more confident?

Biological malfunctions are often the result of a drift (slow or fast) of the physico-chemical parameters of a digester. They are often the result of organic waste supplies not adapted to the operations of the site but constrained by contracts signed with your customers.

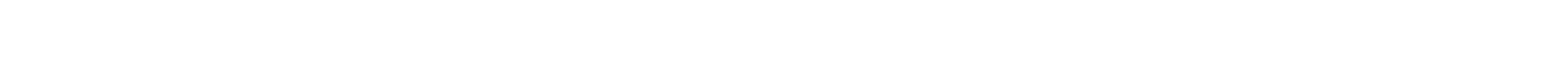

BioEnTech’s tools make it possible to understand the origin of drifts, simulate mixtures (or recipes), correct problematic variations. Anticipating the performance of the process allows you to precisely control revenues and contracts. BioEnTech’s expertise will bring you concrete solutions and ideas to gain profitability and confidence.

How can I quickly know if an unknown substrate is compatible with the biological state of my digester?

Characterization tests are often long and imprecise because the variability of the results is very important between two laboratories. BioEnTech has co-developed with INRAE a reliable and standardized technique to quickly characterize substrates (IR-SCAN®).

How can I secure and correct the biology of my methanization unit?

When biological malfunctions occur, biogas production losses and the organic stabilization time frequently lead to deficits and overcharges (transport to other units, composting, incineration, etc.). Rapid and accurate substrate knowledge (IR-SCAN®) coupled with near real-time laboratory on-site analysis with SNAC® helps to secure, control and correct system drifts.

How do I biologically secure my unit and test a new recipe?

MeMo® allows you to visualize the health status of your digester in real time and to understand how biological parameters drift occurs. MeMo® also allows you to virtually test daily recipes on your facility to avoid biological drifts of the methanizer.

BioEnTech solutions allow you to set your biomethane production caps while adapting to the operating constraints of your collective unit.

Methanization has long been considered a virtuous solution, but it is sometimes difficult to control with all variations and variables. BioEnTech is one of the few players to offer an all-in-one solution, because a methanisation plant requires several biological, technical and scientific know-how.

An advice, a tip, get in touch with us!

We are at your disposal, whatever the size of your unit and your bioprocess is, our teams promote proximity work with your teams.

Each project is studied on a case-by-case basis and BioEnTech solutions are customizable.

Some examples of supported collective activities:

You are:

Site Manager / Collective Unit Operator

Understanding the malfunctions

Anticipating the problems.

Concrete solutions on the ground

Manufacturer of collective units

Innovate and stand out with digital solutions

Real-time biological monitoring and feeding

recommendations

Engineering Office / Project Assistant

Commissioning and loading increase

Improving the biological functioningof the site

Increase your customer’s profitability