Industrial methanisation

Is it possible to consume less electricity and produce less sludge?

Yes, particularly thanks to digital technology in a pragmatic way.

In order to improve the treatment of your organic waste and to recover the energy that comes from it, you have _or plan to _ set up a methanisation plant within your industrial site.

Download the case study

Your contribution to the new circular economy

This initiative makes sense in terms of circular economy and energy optimisation.

Anaerobic digestion not only enables you to comply with new environmental standards, but also to save energy, produce and generate revenue, and reduce your sludge volume.

You participate at your local level in the fight against global warming.

Your benefits (with BioEnTech)

BioEnTech with its multiple industry experience can help you with digital adaptation to:

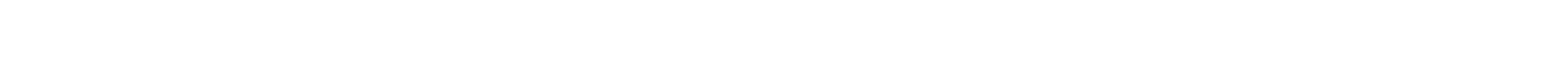

- Know the state of health, stabilising your installation and its biogas plant

- Increase biogas production while reducing the volume of sludge output (by 30 to 50%)

- Reduce the consumption of chemicals and water on site

But also to:

- Understand the source of dysfunctions on your site (inhibitors, reactions)

- Limit your pollution risks

- Benefit from a “green” image as an eco-responsible industrial player

Anaerobic digestion has long been considered a virtuous product, but it is sometimes difficult to control with all variations and variables. BioEnTech is one of the few players to offer an all-in-one solution, because an anaerobic digestion plant requires several biological, technical and scientific know-how.

An advice, a tip, get in touch with us!

We are at your disposal, whatever the size of your unit and your bioprocess is, our teams promote proximity work with your teams.

Each project is studied on a case-by-case basis and BioEnTech solutions are customizable.

Some examples of supported collective activities:

You are:

Chef of Agri-Food

Biodegradable organic loads with high methanogenic power, therefore sources of revenue.

Reduction of energy consumption andchemical consumables.

Savings of up to several k€/year

Creator of cosmetics/perfume

High COD and fat reduction

Characterisation of the organic matter in 5 to 7 days.

Improvement of methanogenesis with 5% more biogas

Writer in the paper industry

80% of inhibition risks and shutdowns avoided.

Keep your granules in shape.

Return on experience validates 50-80 k€/year of benefits

Other industrial

Management of your inputs and operating parameters, real-time optimisation.

Identification of inhibitors in your process

More confident operator