Urban wastewater treatment plants

Is it possible to produce more biogas and minimise the amount of sludge leaving the plant, while complying with strict discharge standards?

Yes, thanks in particular to monitoring, which is digital, scalable and pragmatic.

Methanation is integrated into territorial waste treatment issues by making it possible to recover sludge from urban wastewater treatment plants (UWTPs), to greatly reduce the volumes of final sludge and to produce energy.

In order to improve the sludge process, reduce the costs of your energy consumption, you want to control your municipal sludge methanation unit more serenely and as efficiently as possible.

Moreover, within the framework of the Covid-19 sanitary restrictions, the energy produced by the biomethane will allow you to reduce your costs for the compulsory hygienization of sludge and digestate (thermal drying, thermophilic anaerobic digestion and liming).

French territorial status

In France in 2019, only 76 out of 21,474 urban WWTPs in France will use methanation for wastewater treatment, with one to several anaerobic digesters, while the potential for sludge methanation is not sufficiently developed.

Yet the anaerobic digestion of STEP Urban sludge has many advantages and fits perfectly into a plan of circular economy and energy optimization in a territory.

It not only meets the new environmental standards, but also saves energy, produces energy and lowers operating costs, and reduces your final sludge volume.

The burden on communities for wastewater treatment is constantly increasing, due to the gradual decline in the agricultural recovery of sewage sludge, but above all to the use of technologies that are increasingly costly in terms of electricity. To reduce this phenomenon, more and more stations rely on sludge stabilization by methanization and on the energy recovery of biogas.

An Urban STEP participates at its scale in the fight against global warming while playing a vital health and environmental role in society.

Why so few anaerobic digesters in Urbane WWTP ?

When we ask WWTPs operators this question, they answer us:

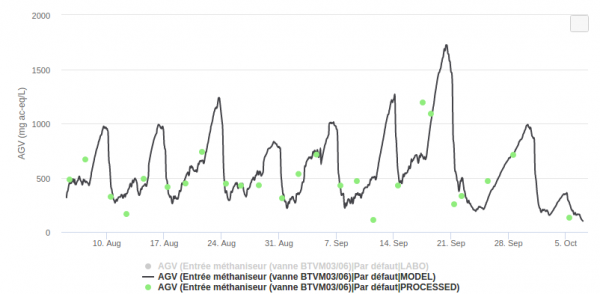

« Methanization requires a very fine and daily follow-up to check the parameters and uncontrolled drifts. It’s a new profession in the field. There is no system that is reliable enough and knowledgeable enough about bio-processes to monitor and indicate the state of the digester in real time. »

The SNAC®, a mini analytical laboratory, is an answer to this question, ideally coupled with the digital solution MeMo®.

What if such a system actually existed to help you, developed in France and with a proven record?

You wish to optimise your biogas methanation process by eliminating as far as possible the risks of acidosis, problems of nitrogen, water condensation in biogas, foaming, and of course tend to valorise biogas as provided by local regulations.

The MeMo® solution with the associated analyses not only provides an optimized energy interest, cuts in water consumption, but also a significant reduction in the volume of chemical reagents, while perfectly fitting into a territorial Energy-Climate plan.

An advice, a tip, get in touch with us!

We are at your disposal, whatever the size of your unit and your bioprocess is, our teams promote proximity work with your teams.

Each project is studied on a case-by-case basis and BioEnTech solutions are customizable.

Some examples of supported collective activities:

You are:

Save your resources

Reduction of energy consumption

Decrease in the use of chemicals.

Gain up to several k€/year

Keep your granules in shape.

Have the support of neighbours

Limit incidents, odours

High COD and fat reduction

Communicate openly

Increase your biogas

In terms of quality

In quantity, 5 to 12% more production

Characterisation of the organic matter in 5 to 7 days.

Accessible Industry 4.0

Management of your inputs and operating parameters, real-time optimisation.

Identification of inhibitors in your process

Operators finally comfortable with methanation